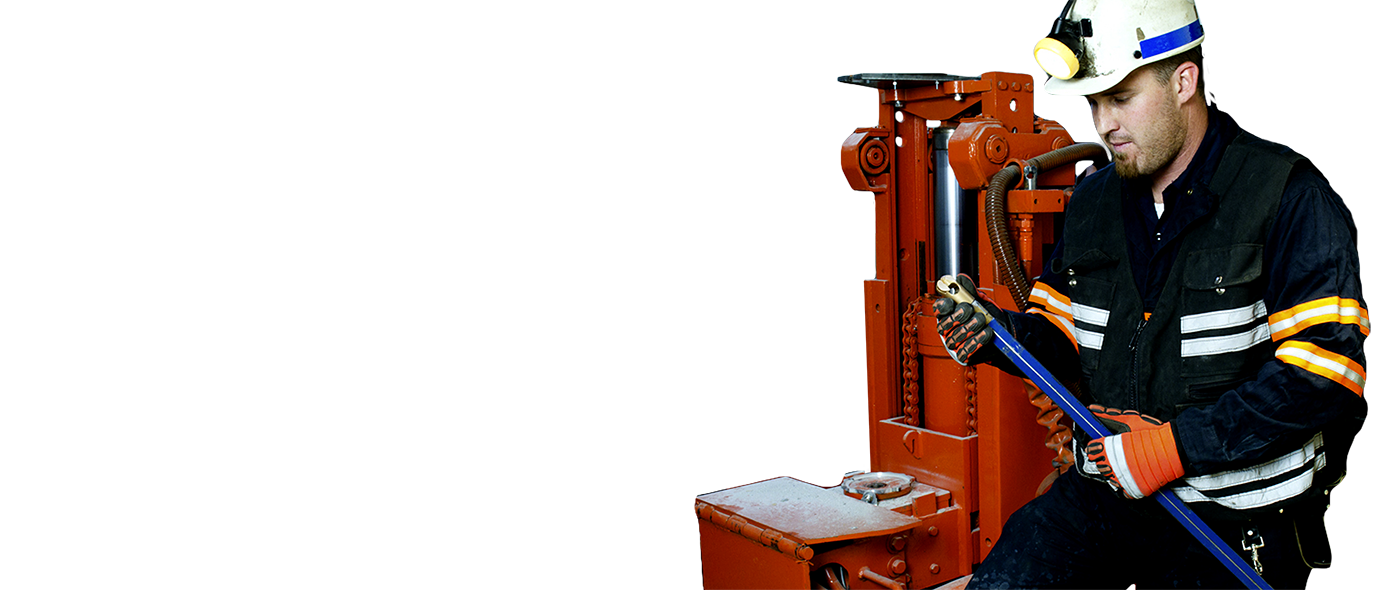

As a result of our ongoing research and development efforts, US Synthetic Mining roof-bolt bits are better able to handle the demanding environments they work in. From diamond powder to the finishing phase, every possible aspect of roof-bolt bit development is monitored, measured and improved.

Our roof-bolt bits use custom-made diamond inserts that are designed and tested to meet the specific needs of our customers. At US Synthetic Mining, we are committed to delivering the best parts now and continuing to innovate in the future to ensure success for our customers in their demanding applications.