Diamond Sintering

The extreme hardness, wear resistance, and thermal conductivity of diamond make it an ideal cutting tool material. However, individual diamond crystals cleave quite easily when struck parallel to certain planes (the process used to facet diamond gemstones takes advantage of these relatively weak planes). As a result, individual diamond crystals do not make good cutting tools—unless they are meticulously oriented.

Diamond sintering overcomes the problem of weak planes in diamond gemstones by bonding a mass of small diamond particles onto a larger, coherent structure. Sintered diamond provides greater toughness and durability than single crystals because the individual crystals in a sintered body are randomly oriented. This prevents cracks from propagating along the weak planes where traditional diamond crystals cleave most easily. Sintered diamonds also provide more uniform wear than a single crystal, while maintaining similar thermal conductivity and hardness properties. All of these factors combine to make sintered diamond the preferred material for cutting rock.

At US Synthetic, the sintering process begins with premium grade diamond crystals. These crystals are sintered together at temperatures of approximately 1400°C and pressures of around 60 kbar in the presence of a liquid metal catalyst. Typically, the diamond is bonded to a tungsten carbide substrate during the same high-temperature, high-pressure process. This sintered diamond and tungsten carbide composite is known in the industry as a polycrystalline diamond cutter (PDC).

Diamond Finishing

The extreme hardness of diamonds presents obvious machining and finishing challenges. In typical machining situations, the finishing tool is harder than the work piece. With diamond inserts, this isn’t possible, since diamond is the hardest known substance. This makes machining diamond analogous to cutting through a wooden beam with a wooden saw. As a result, US Synthetic uses millions of carats of industrial diamond each year to machine and finish PDCs to their final dimensions. Over the years, we have developed specialized techniques and machines for lapping, grinding, polishing, brazing, and cutting PDC inserts. These techniques make it possible for us to finish PDCs to exacting specifications, despite the inherent challenges of machining sintered diamond.

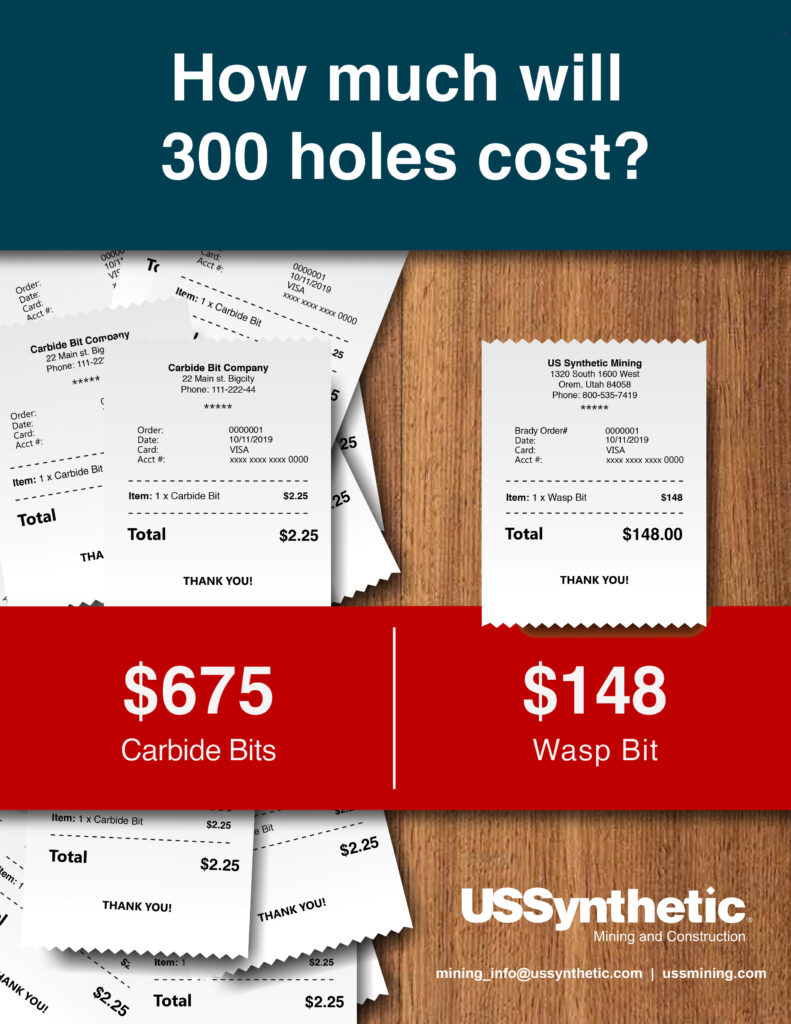

*results vary by location

FEATURES AND BENEFITS

- Drills up to 300 times longer

- Increases tonnage and production

- Penetrates hard rock faster

- Reduces thrust requirements by approximately 75%, increasing drill steel life and eliminating extensive wear on equipment

- Reduces respirable dust by approximately 78%

- Significantly reduces equipment downtime by eliminating the ongoing need to change out worn/broken carbide

The US Synthetic Mining Viper bit brings superior diamond drilling materials and innovative, bit design to offer long-lasting, durable dry roof bolting drill bit.

FEATURES AND BENEFITS

- Drills 50 – 200 times longer

- Increases tonnage and production

- Penetrates hard rock faster

- Reduces thrust requirements by 50%, increasing drill steel life and eliminating extensive wear on equipment

- Reduces respirable dust by approximately 78%

- Significantly reduces equipment downtime by eliminating the ongoing need to change out worn/broken carbide

IMPROVED DIAMOND BITS

US Synthetic Ceramic (Diamond) Wet Bits are new and revolutionary for improving the efficiency and mining costs associated with drilling.

BENEFITS OF DIAMOND BITS:

- Outperform carbide wet drilling by 100 to 300 times longer

- Increase rate of penetration

- Replace percussion drilling

- Reduce drill maintenance

- Lower drill steel cost by reducing thrust requirements and extensive wear

- Significantly reduce equipment downtime by eliminating the ongoing

need to change out and replace worn

or broken carbide wet bits

“The cutting edge of a PDC bit remains relatively sharp throughout its life. (Optimum Thrust, Cutting Speed, and Water Pressure for Tungsten Carbide and Polycrystalline Diamond Compact Roof-Bolt Drill Bits, U.S. Bureau of Mines, 1995.)”

US Synthetic Mining High-Grade Industrial Drill Steel is designed for exceptional strength using high-grade alloy.

INCREASE DURABILITY AND LOWER MINING COST:

- Remains straight under high thrust conditions

- Lasts approximately 20-times longer than traditional drill steel

- Delivers excellent fatigue strength to attain longer life

- Assembled with noise dampening materials

- Incorporated into a universal, easy-to-use shank

- Adapts to most round or hex tubular drill steel extension rods

“…by reducing the number of operations a worker must perform, PDC bits may significantly reduce the number of non-fatal accidents resulting in lost-time injuries, associated with roof-drilling operations. (Special Report, Breakthrough in Roof-bolt Drill Bit Technology, U.S. Bureau of Mines).”

US Synthetic Mining is dedicated to supporting our customers with easy-to-use couplers and custom-designed tooling.

DELIVERED QUALITY TO SUPPORT CONSISTENT PRODUCTION:

- Standard couplings that adapt to most round or hex tubular drill steel

- Unique threaded couplings for secure connections

- Highest quality materials

- Custom-designed applications

- Dedicated engineering support

“PDC bits were operating at one-half the thrust and rotational speed required by the WC-Co bits. (Special Report, Breakthrough in Roof-bolt Drill Bit Technology, U.S. Bureau of Mines).”